TAIWAN SECOM

Brightron Mechatronics

Corporation

KUOHSING SECURITY

GOYUN SECURITY

GOWIN BUILDING

MANAGEMENT

AND MAINTENANCE

GOWIN SECURITY

GOWIN SMART PARKING

LEEBAO SECURITY

LEEBAO TECHNOLOGY

TITAN-STAR

INTERNATIONAL

TAIWAN SECOM

INSURANCE BROKERAGE

SERVICES

TRANSASIA CATERING

SERVICES

EPIC TECH

AION TECHNOLOGIES

Baohwa Trust

eSKYLINK

GOLDSUN

EXPRESS & LOGISTICS

LEE WAY

LOTS HOME

GOLDSUN

BUILDING MATERIALS

TAIPEI PORT TERMINAL

COMPANY

RAIXIN

KUOYUNG

CONSTRUCTION &

ENGINEERING

WELLPOOL

GOLDSUN NIHON CEMENT

TAIWAN SECOM

CULTURAL AND

EDUCATIONAL FOUNDA

RS CONSTRUCTION

GOYU BUILDING

MATERIALS

LIN TENG CULTURAL

AND EDUCATIONAL

FOUNDATION

TAIWAN SECOM

SOCIAL WELFARE

FOUNDATION

DPS

CO., LTD..

GOLDSUN BUILDING MATERIALS CO., LTD.

• Real Estate Development and Management • Concrete • Advisory Service

It has been more than six decades since the establishment of Goldsun in 1954.

Conceived with the idea of goodwill in business with good service and innovative technologies, Goldsun operates 28 concrete plants in Taiwan and 4 concrete plants in Mainland China. Its scale of operation affirms its industry leadership in Taiwan.

Quality Guarantee with Multiple International Accreditations

The Company strives for perfect quality from incoming materials to finished products. It is detail-oriented in operation, which is the promise of Goldsun to its customers.

Goldsun was the first enterprise of its kind in the industry of Taiwan accredited with the SGS ISO9001 quality system in conjunction with the “Republic of China Good Ready-Mixed Concrete System (GRMC),” and the “CNS Standard to Assure Product Quality.”

The Company was first accredited in 1997 and 19 of its plants are accredited so far. The plants in Taipei, Bali, Taipei Port, Zhongli, Taichung, Dahu, and Tainan have been awarded the label of Good Quality Products, demonstrating Goldsun's compliance with ISO9001 production standards.

Innovation in Research and Development Ensures Competitive Power

Goldsun seeks to upgrade its overall competitive power in the industry and reduce its cost of production through coordination with the industry, government, and academia through its R&D Center. Under such concerted efforts, Goldsun can bolster its design and development of ready-mixed concrete products, upgrade its quality control techniques,

and integrate its consultation service.

In the area of research and development, the Company is not bound by traditional modes of

operation in order to ensure satisfaction to diverse customer needs, and thereby transform the specific feature of hardness and stability of concrete into stylish aesthetic products. In the area of production process, it matches its patents, expertise in human resources, research and development capacity, policy and laws, and industry needs in research and development to condense the time of production, save manpower, and simplify the production process.

Product Item

▪ “Shimizu” Architectural Concrete

▪ High Density Concrete

▪ Self Filling Concrete

▪ Pervious Concrete

▪ Green Concrete

▪ Impermeable Concrete

▪ High Strength Concrete

▪ Roll Compacted Concrete

▪ Lightweight Aggregate Concrete

Sales Performance

▪ Taipei Bus Station

▪ Taipei City Hall Bus Station

▪ HTC Corporation Taoyuan Factory

▪ Taipei NanShan Plaza

▪ E-DA World

▪ Renai The Royal Palace

▪ Canon Bonded Factory

A Wealth of Experience to Give Customized Solutions

With more than 60 years of experience in the concrete business, Goldsun provides custom-made solutions for customers. Attuned to customer needs and combined with its research and development capacity, Goldsun provides a wide array of ready-mixed concrete for different architecture structures, construction methods, and design needs. It also differentiates its products to meet the needs of modernized architecture structural design and the requirement of hardness and stability.

Peace of Mind Construction Project 160,000,000m³ Guarantee Living

Goldsun established its customer service center to show its confidence in operation and hear the voice of every customer with timely improvement. For over 60 years, Goldsun lives up to this philosophy. Goldsun has customers all over Taiwan and its sales service teams cover the whole island. One can find the work of Goldsun in constructions and bridges everywhere in Taiwan. Goldsun seeks to create a safe and comfortable living environment for the public.

Building Traceability Through Vertical Integration

“Possession of resources in stable supply will be the optimal competitive power”. With its professional management experience, Goldsun established the “one-stop production of products” through vertical integration of operations from raw materials to finished items. From investment in mineral mines, establishment of a sea and land transportation team, operating a bulk cargo dock, and establishment of a slag grinding plant, Goldsun itself supplies the majority of raw materials needed for ready-mixed concrete. Through precision calculation of the timing of each stage of operation, the Company provides a complete product line and ensures good quality with upgraded production efficiency.

Balance of Quality and Quantity With Stable Sources of Supply and Quality of Materials

Goldsun has invested in aggregate mines and exercises strict procurement controls to ensure stable sources of supply and production quality, and to prevent possible contamination of the quality and quantity inherent to natural resources. With the use of centrifugal grinding equipment in the production of “processed aggregate”, Goldsun can finish the coarse surface of the materials and sort out the size, shape, and quantity of the materials in mixing with control. The aggregate is as good as natural materials with the desired functional properties, high strength, and durability, and can satisfy the needs of high strength and customization through various ratios of mixing as needed.

Sea-Land Logistics Support for Flexible Delivery

Goldsun owns its own fleet for marine transport and procured bulk carriers for flexible assignment of delivery in high capacity. In addition,Goldsun also has its own vehicle fleet for land transport of aggregate, which operate in conjunction with the logistics support of GSE (Goldsun Express & Logistics Co., Ltd.) and our concrete transport fleet. All dispatches are assisted by smart GPS. With monitoring and control bia visual display, data analysis and color management in the dispatch and assignment, the traffic in the surrounding areas of the work site runs smoothly so that works in progress will not be interrupted and quality of work can be assured. Goldsun assists customers to upgrade corporate image and satisfaction.

Traceability Management for Full Disclosure of History of Materials

Goldsun insists on the disclosure of the history of its materials to ensure the material safety of their construction projects, and work in cooperation with the Taiwan Construction Research Institute, SGS, and the Institute for Information Industry to launch the “Traceability of Construction Materials” website, the first of its kind in Taiwan. The public may simply scan the “QR CODE” on the wall of the buildings to disclose the mineral source of the gravel, the strength of the concrete, the grouting date, the chloride test report, and related information. With this information, the public can understand the quality of the construction materials in addition to the physical appearance of the building, and can have peace of mind about the strength of the building structure.

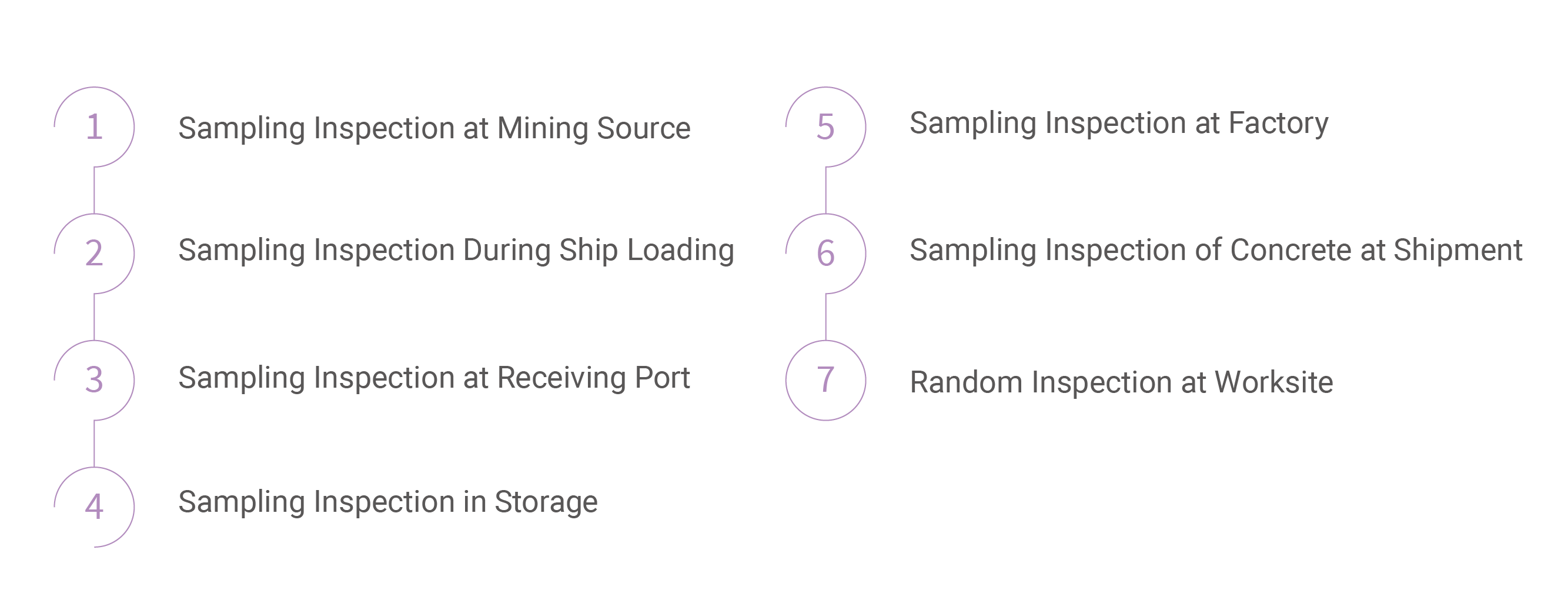

7-Stage Inspection to Detect the Presence of Chloride

Goldsun spares no effort in eliminating the presence of sea sand in its products, and thereby dispatches its personnel to station at the point of embarkation of materials for monitoring and control, and conducts inspection before loading for shipment. This arrangement is to assure no effect of the salt from sea water in the course of marine transport of its materials, hence maintaining product quality at the time of unloading at the dock. Before the materials are dispensed to production, IQC inspection will be conducted before acceptance. All aggregate will be subject to daily inspection and analysis to maintain quality and the stability of the content of chloride with the issuance of the “Quality Assurance Certificate” and “Chloride Inspection Report” for assurance of superior quality before shipment and production.